copper tungsten contact

Classification :

Copper Tungsten alloy

Tungsten Copper

Description :

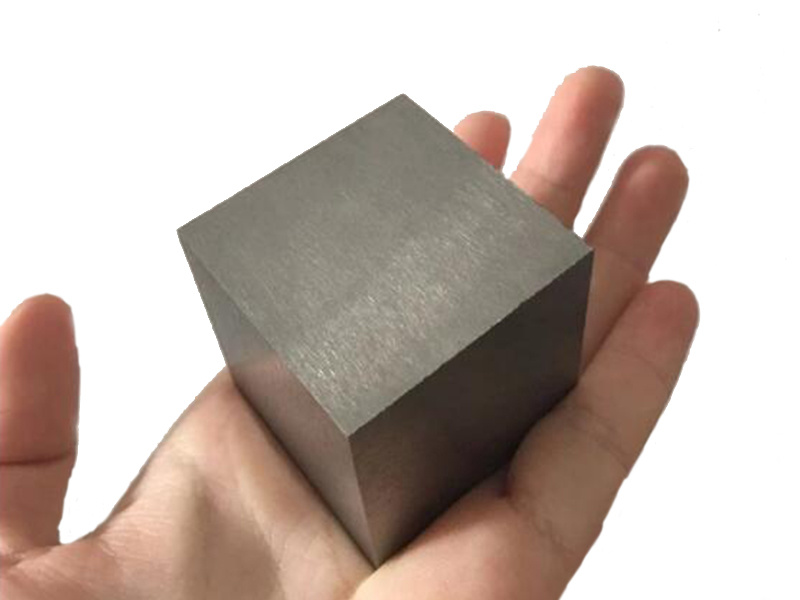

Copper tungsten contacts Owing to the good performance of electrical conductivity, tungsten copper contact can be used as electrical contact material, The high electrical and thermal conductivity of copper are combined with the arc-resistant and non-welding properties of tungsten or their carbides to form an extensive series of compositions. Each is designed to give the best performance for your particular application.

Keywords :

Email:

copper tungsten contact

Copper tungsten contacts Owing to the good performance of electrical conductivity, tungsten copper contact can be used as electrical contact material, The high electrical and thermal conductivity of copper are combined with the arc-resistant and non-welding properties of tungsten or their carbides to form an extensive series of compositions. Each is designed to give the best performance for your particular application.

We are able to influence the copper tungsten contacts’ arc erosion properties by choosing the right mixture of tungsten and copper. With tungsten content reaching at 80 %, we achieve the lowest arc erosion rates. Depending on the voltage and current intensity as well as on economic considerations, we can vary the tungsten content between 50 and 93 % to meet the exact needs of clients' application.

For switch contacts, we also have copper tungsten carbide contacts or CuWC contacts for your inquiry. With high density, high strength and hardness, arc wear resistance, copper tungsten carbide contacts is wildly used as the electrical contact and electrode too.

Tungsten Copper Contacts

Tungsten copper contacts is an alloy composite of tungsten and copper, which include both excellent properties of tungsten and copper, such as heat resistance, aberration resistance, high density, excellent thermal and electrical conductivity. Tungsten copper contacts are the best suitable material for electrical discharge machining (EDM) applications. It has excellent wear resistance, good metal removal rate and ability to retain good detail.

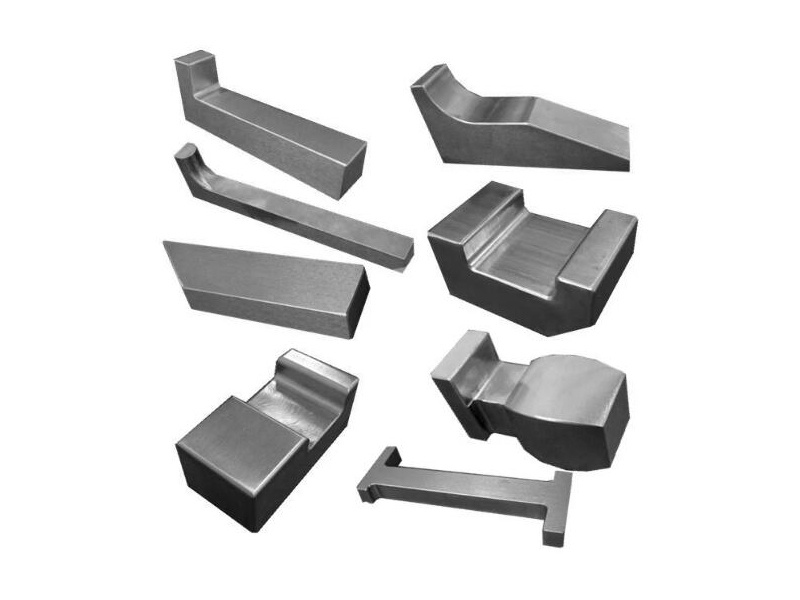

Copper Tungsten Contact Parts

Copper tungsten contact parts maintain quite regular shape under extreme arcing conditions and have only uniform roughening effect without cracks and burn-off droplets. Copper tungsten contact parts find applications in SF-6 circuit breaker, load break switches, transformer step switches, and resistance welding electrode and spark erosion electrodes.

Copper Tungsten Contact Tips

Copper tungsten contact tips maintain quite regular shape under extreme arcing conditions and have only uniform roughening effect without cracks and burn-off droplets. Copper tungsten contact tips find applications in SF-6 circuit breaker, load break switches, transformer step switches, and resistance welding electrode and spark erosion electrodes.

Tungsten Copper Arc Contact

Tungsten copper arc contact is used for arcing contacts in SF6 circuit breakers for ultra high, high and medium voltage applications. At the heart of the switching chamber, tungsten copper contacts are exposed to extreme mechanical and thermal loads: When the circuit is opened and closed, the arc starts directly at the switch contacts at a temperature of up to 20 000 °C.

Tungsten Copper Contacts Spares

Tungsten copper contacts spares are subjected to extreme mechanical and thermal stresses during operation. For fractions of a second, temperatures rise to several thousand degrees as a result of the arcing. Only tungsten copper materials will stand these high temperature & aberration.

Tungsten Copper Electrical Contacts

Tungsten copper electrical contacts are best suitable material for electrical discharge machining (EDM) applications. It has excellent wear resistance, good metal removal rate and ability to retain good detail. It is used where speed and wear resistance are most important.

Tungsten Copper Spring Contacts

Tungsten copper spring contacts with excellent resistance arc burning and welding resistance, breaking arc performance, good thermal conductivity, thermal expansion, high temperature does not soften, high strength, high density, high hardness and other characteristics.

Tungsten Copper Fiber Structured Contact

Tungsten copper fiber structured contact materials is better than that of power metallurgical ones and ablation of small diameter fiber-structured contact materials are superior to that of large diameter ones. Which have not only high melting point, high density, low thermal coefficient of expansion and high strength, but also better electric conduction, better heat conduction and plasticity under room temperature.

Tungsten Copper Arcing Contacts for SF6 Circuit Breakers

Tungsten copper materials are used for arcing contacts in SF6 circuit breakers for high and medium voltage applications. At the heart of the switching chamber, tungsten copper arcing contacts are exposed to extreme mechanical and thermal stresses. During arcing, the temperature can reach levels ≥ 20,000 K, for instance.

Tungsten Copper Vacuum Contacts

Tungsten copper contacts are used in the vacuum arc-quenching chambers (VACs) of highly dependable, quick-acting vacuum circuit breakers capable of breaking large currents in high-voltage 6-35 kW electrical networks. Tungsten copper vacuum contact is a key element in commutation switches (circuit breakers). Currently, the most common material used in contact pairs in VACs are W-(50-90%)Cu composites.

Tungsten Copper High Voltage Arc Contacts

We offers a complete range of tungsten copper high voltage arc contacts depending on the combination of electric arc resistance and electrical conductivity, our customers will always be able to find the right contact material that will contribute to the performance of the electric apparatus.

Tungsten Copper Combination Contact

Tungsten copper combination contact, as the name suggests it is combined by tungsten copper with other material. As usual, the shank of contact is iron, and the end of contact is tungsten copper. Contract with general tungsten copper contacts, the advantage of combination contact is the lower costs. But it is very suitable for which some of industry only required high quality in the end of contact, the combination contact could save much costs but also with high properties.

Previous

Next

Previous

none

Next

RELATED PRODUCTS

PRODUCT MESSAGE