Molybdenum Copper Heat Sink

Classification :

Heat Sink

Description :

Molybdenum Copper Heat Sink Applications: electronics packages, Microwave Packages, IC Packages,IPC base plate, Laser Submounts

Keywords :

Email:

Molybdenum Copper Heat Sink

Molybdenum Copper Heat Sink Applications: electronics packages, Microwave Packages, IC Packages,IPC base plate, Laser Submounts

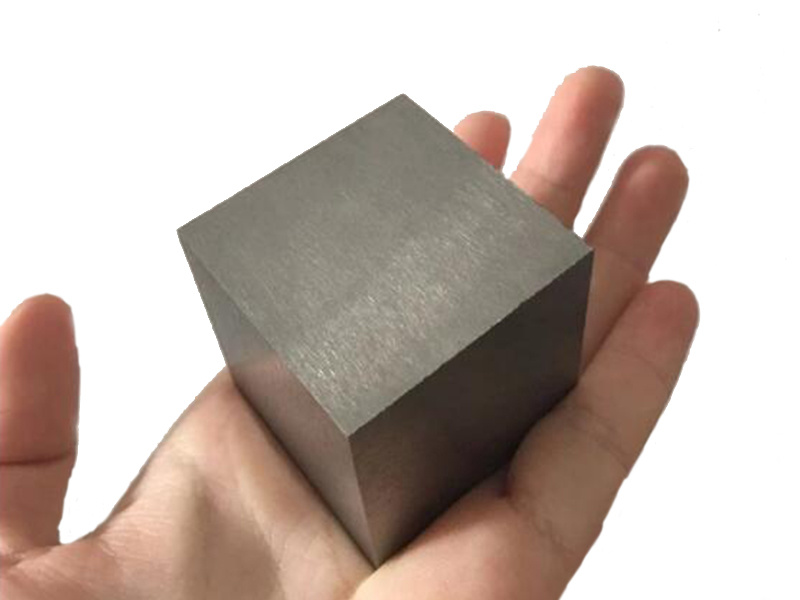

Molybdenum Copper Heat Sink

Moly-Copper heat sink Consists of metal elements molybdenum and copper alloy

As a copper tungsten product, tungsten copper heat sink is a composite. So both the thermal advantages of copper and the very low expansion characteristics of tungsten can be utilized.

The combination of these two materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates.

.

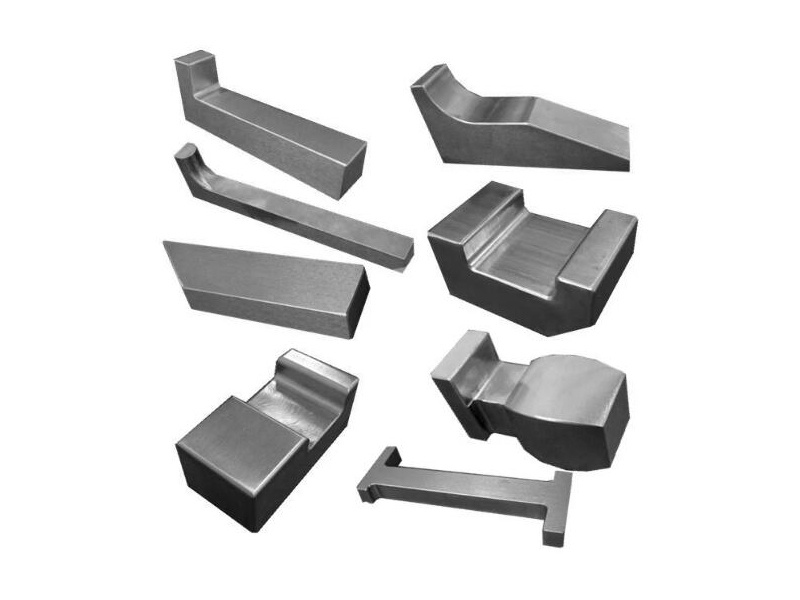

* MoCu: Molybdenum-Copper Laminates

They are composites of molybdenum and copper. Similar to W-Cu, CTE of Mo-Cu can also be tailored by adjusting the content of molybdenum. Mo-Cu is much lighter than W-Cu so that it is suitable for aeronautic and astronautic applications.

Our products are widely used in applications such as electronics packages, Microwave Packages, IC Packages,IPC base plate, Laser Submounts etc.

Advantages

o High thermal conductivity since no sintering additives have been used

o Excellent hermeticity

o Relatively small density

o Stampable sheets available (Mo content no more than 75 wt%)

o Semi-finished or finished (Ni/Au plated) parts available

Physical Properties of Major Products

|

Grade |

Molybdenum Content |

Copper Content |

Density g/cc at 20? |

Thermal conductivity at 25? |

Coefficient of thermal expansion at 20? |

|

Mo85Cu15 |

85±1 |

Balance |

10 |

160-180 |

6.8 |

|

Mo80Cu20 |

80±1 |

Balance |

9.9 |

170-190 |

7.7 |

|

Mo70Cu30 |

70±1 |

Balance |

9.8 |

180-200 |

9.1 |

|

Mo60Cu40 |

60±1 |

Balance |

9.66 |

210-250 |

10.3 |

|

Mo50Cu50 |

50±0.2 |

Balance |

9.54 |

230-270 |

11.5 |

Previous

CuMoCu

Next

RELATED PRODUCTS

PRODUCT MESSAGE